PRESS RELEASES

A&M Industrial Introduces Autobrade Robotic Surface Finishing Systems To U.S. Manufacturers

JULY 2025

The Future Of Surface Finishing Has Arrived

A&M Industrial, a leading distributor of industrial supply and automation solutions, proudly announces the addition of Autobrade™ Robotic Surface Finishing Systems to its growing lineup of advanced manufacturing technologies. Designed to enhance safety, consistency, and efficiency, Autobrade delivers a smart alternative to manual surface finishing in today’s labor-constrained manufacturing environment.

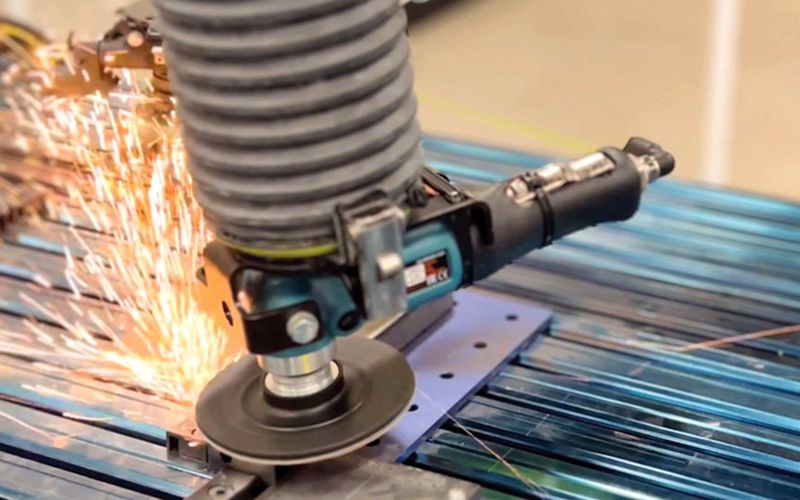

As U.S. manufacturers grapple with skilled labor shortages, rising costs, and demanding quality standards, Autobrade robotic systems offer a powerful solution for automating deburring, sanding, polishing, and grinding tasks. These ready-to-deploy systems not only reduce operator exposure to hazardous environments but also improve throughput and product uniformity across a range of materials—including metal, composites, plastics, and wood.

At the core of the system is the Autonomous Adaptable Robotic System (AARS), powered by MARI (Maple Advanced Robotics Inc.) technology. With intuitive Scan & Go functionality and Drag & Go no-code programming, AARS empowers non-technical users to program robots up to 20 times faster—streamlining implementation and accelerating ROI. Autobrade’s modular design pairs with the Active Contact Flange-Kit (ACF-K) and the industry’s widest range of robotic end-effectors for unmatched application flexibility.

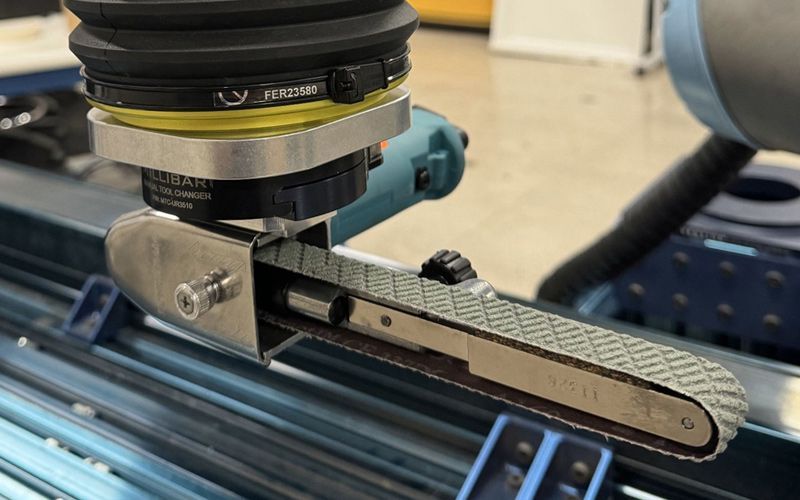

Autobrade systems are fully compatible with leading robot brands including FANUC, Universal Robots, and Doosan, and integrate seamlessly with Dynabrade end-of-arm pneumatic tools. For panel finishing operations, Autobrade also offers a fully integrated robotic work cell featuring a two-tool system that simultaneously processes rail faces and inner pockets—eliminating tool changeover with an innovative dual-head configuration.

“Autobrade represents the next evolution in surface finishing,” said Josh Young, Chief Operating Officer at A&M Industrial. “By pairing Autobrade’s innovative technology with our in-house robotic expertise and support services, we’re helping customers automate their most labor-intensive finishing tasks and unlock real efficiency gains.” Through its A&M Robotics division, A&M Industrial supports clients from concept to installation and beyond—offering end-to-end services that include system design, integration, programming, and training. With the addition of Autobrade, A&M Industrial continues to expand its role as a trusted automation partner for U.S. manufacturers looking to improve safety, productivity, and product quality through smart, scalable robotics solutions.

Learn more about Autobrade robotic surface finishing at

www.am-ind.com/robotics

SOURCE: A&M Industrial

About A&M Industrial:

A&M Industrial is a leading independent industrial supply distributor with branches across the East Coast, primarily serving the industrial manufacturing industry in the United States. A&M Industrial offers over one million maintenance, repair, and operations (MRO) products, metalworking and machining tools, plus a wide variety of safety and PPE solutions, PVF products, process system equipment, and more. Renowned throughout the industry for their experienced staff and know-how, A&M Industrial provides an extensive range of services designed to increase customer productivity, efficiency and safety. Since 1954, A&M Industrial has continued to build a legacy upon founder Arny Young’s core principle: put people first, and success will follow.

Media Contact:

Mark Abraham

mabraham@am-ind.com